Introduction

An intercooler is a critical component in modern turbocharged and supercharged engines. Its main function is to cool compressed air before it enters the engine. By lowering the air temperature, this system increases air density, allowing more oxygen to reach the combustion chamber. The result is improved engine performance, increased horsepower, and better fuel efficiency. Whether you are an automotive enthusiast or a professional mechanic, understanding how a compressed air cooler works is essential to maximizing your engine’s potential.

How Intercoolers Work

These heat exchangers work by transferring heat from the hot compressed air to either ambient air or a coolant. When air is compressed by a turbocharger or supercharger, it becomes hot. Hot air is less dense, containing less oxygen for combustion. Cooling the air before it enters the engine allows for denser fuel mixtures, improving combustion efficiency, reducing the risk of engine knock, and enhancing overall performance.

Air-to-air systems use airflow from the vehicle’s motion to remove heat from the compressed air. The hot air passes through the cooling core, exchanging heat with the cooler outside air. Air-to-water systems, on the other hand, use a separate coolant circuit to maintain consistent air temperatures. Both approaches are effective, but proper design and maintenance play a key role in achieving optimal results.

Types of Intercooler Systems

There are two main types of compressed air coolers: air-to-air and air-to-water.

Air-to-air systems are the most common. They rely on ambient airflow to lower the temperature of the intake air. These units are generally mounted at the front of the engine bay and are sufficient for most street vehicles.

Air-to-Water Systems are used in high-performance or space-constrained setups. They employ a coolant system to reduce air temperature more effectively, even under prolonged high-speed driving. Air-to-water setups provide consistent cooling in extreme conditions, making them ideal for racing or heavily modified engines.

The placement of the cooling system also affects performance. Front-mounted units provide maximum airflow and cooling efficiency, while top-mounted designs are used in vehicles where engine bay space is limited. Understanding the type and placement helps select the right solution for your vehicle.

Components and Design Considerations

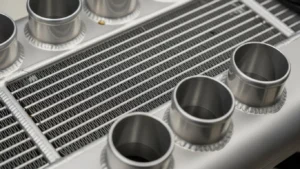

The design of these heat exchangers directly impacts efficiency. Core size, piping, and fins are crucial factors that determine how effectively heat is dissipated. Larger cores with optimized fin design allow more air to pass through while minimizing pressure loss. Aluminum is commonly used for its high thermal conductivity, lightweight nature, and durability.

Proper design reduces turbulence within the system, ensuring consistent airflow and optimal cooling. Performance enthusiasts often upgrade cores, piping, and end tanks to enhance engine power. Understanding these design aspects allows you to select a compressed air cooler that matches your performance goals.

Benefits of Compressed intercooler

Upgrading or maintaining a high-quality compressed air cooler offers multiple benefits:

-

Increased Horsepower and Torque: Cooler, denser air allows for better combustion, resulting in higher power output.

-

Reduced Detonation Risk: Lower intake temperatures prevent premature combustion, protecting the engine.

-

Improved Fuel Efficiency: Enhanced combustion efficiency helps the engine use fuel more effectively.

-

Enhanced Engine Longevity: Cooler intake air maintains stable engine temperatures, reducing wear on critical components.

These advantages make these cooling systems essential for anyone looking to improve engine efficiency and performance.

Common Issues and Maintenance

Even the best systems can develop problems over time. Heat soak occurs when the unit absorbs too much heat from the engine, reducing cooling efficiency. Leaks or pressure drops can also impact performance, lowering boost levels and restricting airflow.

Regular maintenance, including cleaning the core and checking for leaks, ensures consistent performance. Proper care extends the lifespan of the system and maintains engine reliability.

Performance Upgrades and Installation Tips

Performance enthusiasts often upgrade their compressed air coolers to maximize horsepower and reduce intake temperatures. When selecting an upgrade, consider the engine’s power requirements, type of driving, and available space in the engine bay.

Front-mounted systems provide superior cooling efficiency for high-speed applications. Air-to-water setups offer consistent performance for racing vehicles. Upgrading piping, core size, and end tanks can further enhance airflow and reduce pressure drop. Professional installation ensures optimal fitment and performance.

Comparing the intercooler to Other Cooling Systems

A compressed air cooler is often confused with a radiator. While a radiator manages engine coolant to maintain overall engine temperature, a compressed air cooler specifically cools the intake air from forced induction systems. Both contribute to engine performance and longevity but serve different purposes. Understanding these differences helps when deciding which system to upgrade or maintain for optimal results.

FAQs

Can any engine benefit from a compressed air cooler?

Most turbocharged or supercharged engines can see performance improvements. Naturally aspirated engines usually do not require such systems.

Does a cooler intake air system increase horsepower?

Yes. Cooler air allows for denser fuel-air mixtures, improving combustion efficiency and increasing power output.

Air-to-Air or Air-to-Water intercooler: which is better?

Air-to-air systems are sufficient for most street vehicles, while air-to-water systems are preferred for high-performance or racing applications.

Conclusion

A well-designed intercooler is vital for improving engine performance, protecting against heat-related issues, and enhancing fuel efficiency. Understanding its operation, types, design considerations, and maintenance requirements allows car enthusiasts and professionals to make informed decisions. Upgrading to a high-quality system can significantly enhance vehicle efficiency and reliability.